Last weekend Geri Instagrammed a photo of the drying rack at the Printing and Book Arts Center at the Genesee Center for the Arts and Education (that's a mouthful). Reaction was over the moon! I think the outpouring of love was based on the simple fact that the heart of the drying rack is the beloved Slinky®, favorite toy of child and adult alike.

(Fun Fact: Rochester, New York, is home to the National Museum of Play where the Slinky was inducted in 2000 into its "Toy Hall of Fame.")

— The Slinky Drying Rack's Journey to Greatness —

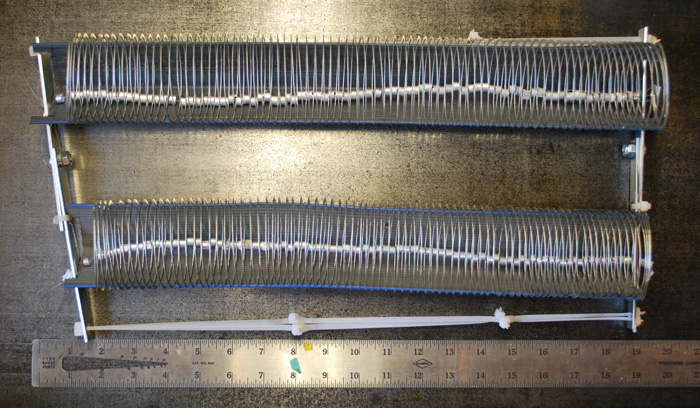

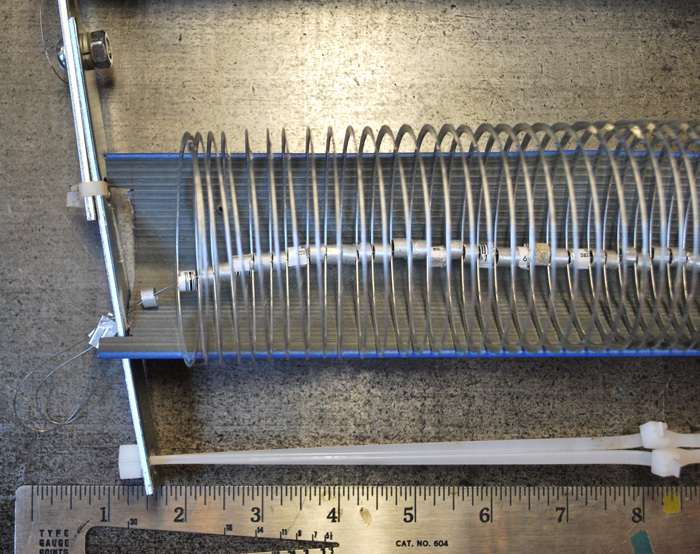

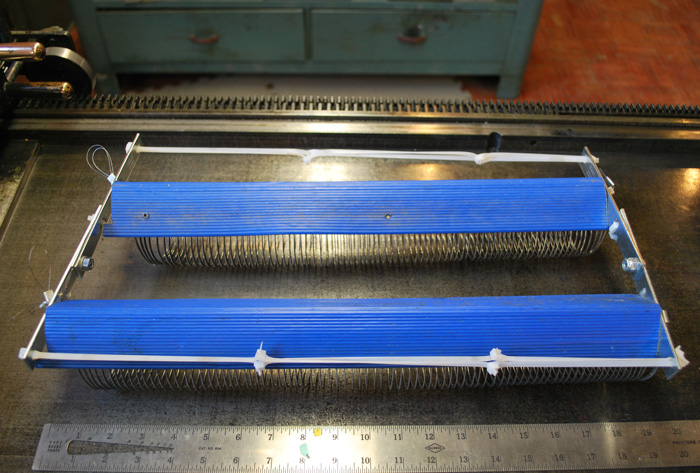

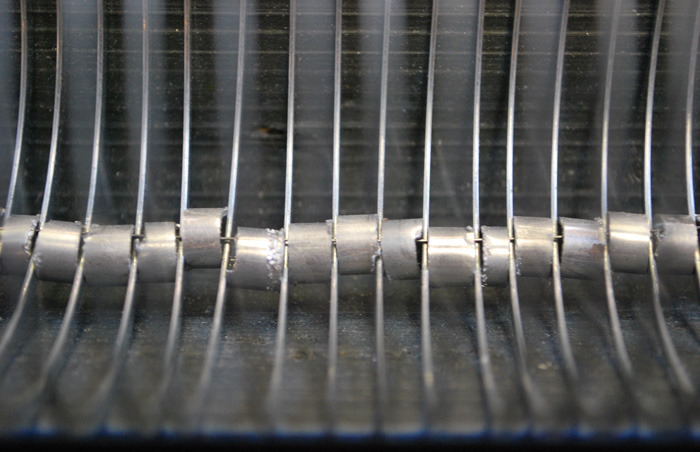

About a year ago a single Slinky Drying Rack appeared at the Genesee Center as an experimental solution to the on-going problem of where to dry freshly printed pieces in the space-constrained center. The single Slinky did not hold up paper larger than a postage stamp. The second revision beefed up the base but did not solve the paper-holding problem. The third and final revision added the second Slinky, which expanded the footprint, and the separators were added between the Slinky ribs. Voilá! Works like a charm.

We thought it'd be fun to show detailed photos of the Slinky Drying Rack's construction and provide instructions on how you could make your own. Full disclosure: I did not design nor construct this. These instructions are simply guidelines. Feel free to improve upon the design. OK, now lets put on our safety glasses and ear protection and get to work.

— Materials —

— Tools —

— Instructions —

Post photos of your own Slinky Drying Rack.

Shop Class Dismissed.

— Photos —

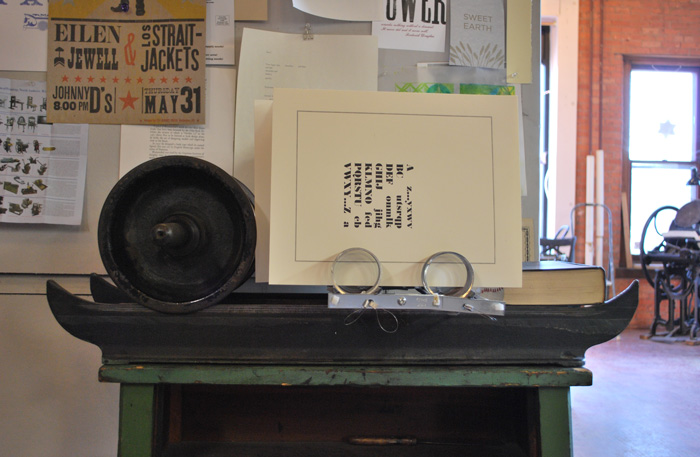

Slinky Drying Rack in use this morning. One never finds it in the same place twice. Here it is sitting on a sled press, holding alphabet projects of students taking Letterpress I at the Genesee Center.